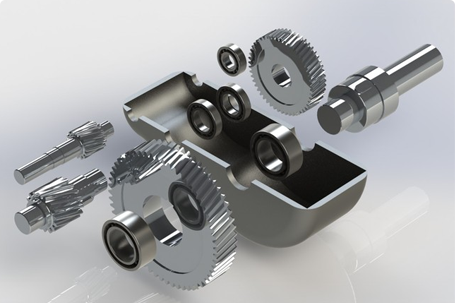

The working principle of the gear reducer is based on the meshing relationship between gears, and the effects of speed reduction and torque increase are achieved through a combination of gears of different sizes. The following is a detailed description of the working principle of the gear reducer:

Input and output shafts: Gear reducers usually include an input shaft and an output shaft. The input shaft is the shaft that transmits power, while the output shaft receives the transmitted power and outputs decelerated rotation.

Driving gear and driven gear: The gears in a gear reducer are mounted on the input and output shafts. The gear on the input shaft is called the driving gear, while the gear on the output shaft is called the driven gear.

Gear meshing: As the input shaft rotates, the teeth of the drive gear mesh with those of the driven gear. This meshing relationship allows the rotation of the driving gear to be transmitted to the driven gear.

Gear ratio: The number of teeth of the driving gear and the driven gear determines the reduction ratio of the gear reducer. If the driving gear has more teeth and the driven gear has fewer teeth, the output shaft speed will decrease but the torque will increase.

Direction of rotation: The gear reducer can change the direction of rotation between the input shaft and the output shaft. By selecting the appropriate gear combination and layout, forward or reverse output rotation can be achieved.

Efficiency and energy loss: The transmission efficiency of the gear reducer depends on factors such as the design and manufacturing quality of the gear, as well as the lubrication condition. During the transmission process, there will be a certain amount of energy loss, and this energy is lost in the form of heat.

By rationally selecting the gear ratio and layout of the gear, the gear reducer can achieve different reduction ratios and output torques to meet the needs of different applications. They are widely used in various mechanical transmission systems to provide reliable speed reduction and torque increase functions.

05 Jun,2025

05 Jun,2025