In the intricate world of mechanical engineering and power transmission, gears play a crucial role in ensuring efficiency and reliability. Among the diverse types of gearboxes, the spiral bevel gearbox stands out due to its unique design, smooth operation, and versatility. Whether in automotive applications, aerospace engineering, or heavy machinery, spiral bevel gearboxes are critical components for transferring power with minimal loss and optimal performance.

What is a Spiral Bevel Gearbox?

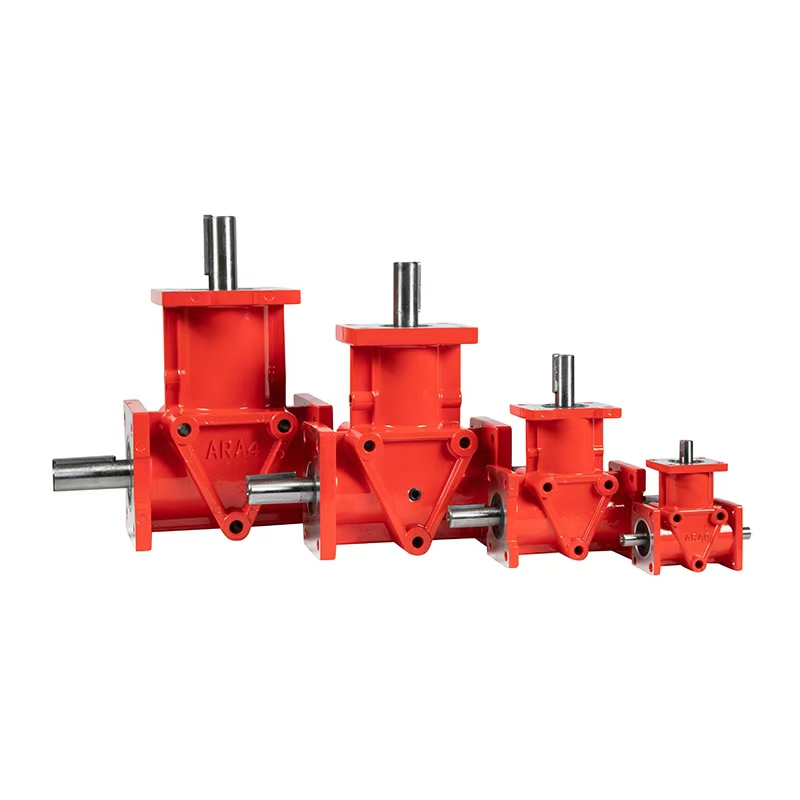

A spiral bevel gearbox is a type of bevel gear system designed to transmit power between shafts that are typically at a 90-degree angle to each other. The spiral bevel gear's unique feature lies in the angle and curvature of its teeth, which differ from traditional straight bevel gears. This design allows for smoother and quieter operation, making it ideal for high-performance applications where noise reduction and precision are paramount.

Spiral bevel gears are named after their tooth geometry, which spirals along the face of the gear. The teeth are cut at an angle, allowing for gradual engagement between gears, as opposed to the abrupt engagement seen with straight bevel gears. This results in higher load-bearing capacity, increased efficiency, and less wear over time.

Design Principles Behind Spiral Bevel Gearboxes

The spiral bevel gearbox is engineered to meet the demands of various industries. The gears are typically made of high-strength steel or other durable materials to ensure that they can withstand heavy loads and harsh conditions. The design of the spiral bevel gear ensures a smooth transition of power between the shafts, thereby reducing the amount of energy lost during transmission.

In contrast to straight bevel gears, which have teeth that are cut along the pitch cone of the gear, spiral bevel gears have teeth that are cut at a helix angle. This arrangement allows for better contact between the teeth during operation, leading to smoother engagement and reduced noise. The design also minimizes the chances of gear tooth breakage, which is essential for ensuring the longevity and reliability of the gearbox.

Applications of Spiral Bevel Gearboxes

Spiral bevel gearboxes are used in a wide range of applications where high torque and efficiency are required. They are particularly prevalent in industries that demand high-performance machinery, such as the automotive, aerospace, and robotics sectors.

Automotive Industry

In the automotive sector, spiral bevel gearboxes are used in differential gears, allowing for the smooth transfer of power between the driving axle and the wheels. The unique spiral tooth design in these gearboxes enables efficient torque transfer and helps in minimizing noise and vibrations, thereby improving the overall driving experience.

Aerospace Engineering

Aerospace applications demand gear systems that can function under extreme conditions. Spiral bevel gearboxes are often used in aircraft transmissions, where they must handle high-speed rotations and significant loads. The ability to maintain smooth power transmission in such challenging environments makes spiral bevel gearboxes indispensable in aerospace engineering.

Robotics and Automation

The precision and smoothness of spiral bevel gears make them ideal for robotics and automated systems. In these applications, gearboxes must provide consistent performance with minimal backlash and wear. Spiral bevel gearboxes, with their superior load distribution and efficiency, are well-suited to meet these stringent requirements.

Advantages of Spiral Bevel Gearboxes

The spiral bevel gearbox offers several advantages over other types of gear systems, making it the preferred choice in various industries.

Smooth Operation: The spiral bevel gear's tooth design ensures smoother engagement, reducing noise and vibration. This makes it ideal for applications where noise reduction is critical, such as in automotive and aerospace sectors.

High Load Capacity: The angled teeth of spiral bevel gears allow for greater contact surface area, which in turn increases the load-carrying capacity of the gearbox. This makes them ideal for heavy-duty applications that require high torque.

Durability and Longevity: The design of the spiral bevel gearbox ensures minimal wear and tear over time. The gradual engagement of the gear teeth reduces the chances of gear failure, leading to longer service life and reduced maintenance costs.

Efficiency: Spiral bevel gearboxes are highly efficient in power transmission, with minimal energy loss compared to other gear systems. This efficiency translates into reduced operating costs and improved performance.

Versatility: Spiral bevel gearboxes can be customized to meet the specific needs of different applications. Whether it's a compact design for a small mechanical system or a large, heavy-duty gearbox for industrial machinery, spiral bevel gearboxes offer flexibility in design and function.

Challenges and Considerations

While spiral bevel gearboxes offer numerous advantages, they are not without their challenges. One of the primary concerns when designing and manufacturing spiral bevel gears is the complexity of their production process. The precise cutting of the gear teeth at an angle requires specialized machinery and skilled labor, which can increase the cost and lead time for manufacturing.

Due to the angled teeth, spiral bevel gears experience a higher level of stress and heat generation during operation. As a result, careful attention must be paid to lubrication and heat dissipation to ensure the long-term performance of the gearbox. In high-load applications, the gears may require frequent maintenance to ensure that they remain in optimal working condition.

Maintenance and Lubrication of Spiral Bevel Gearboxes

Proper maintenance is essential to ensure the longevity and efficiency of a spiral bevel gearbox. Regular inspection of the gears and bearings is necessary to detect any signs of wear or damage. The gearbox should be properly lubricated to reduce friction and prevent overheating. Using high-quality gear oil that is suitable for the operating conditions is crucial in maintaining the gearbox's performance.

Spiral bevel gearboxes play a vital role in the efficient transmission of power in various industries. Their unique design, which features angled, spiral-shaped teeth, allows for smooth, quiet, and efficient operation, making them an ideal choice for high-performance applications. From automotive differentials to aerospace transmissions, spiral bevel gearboxes are integral components in modern machinery and equipment.

As industries continue to evolve and demand more efficient, durable, and precise power transmission solutions, the spiral bevel gearbox will remain a crucial component in achieving these goals.

05 Jun,2025

05 Jun,2025