Introduction: Industry Context and Importance of Hypoid Reducers

In modern industrial systems, power transmission components serve as the backbone of mechanical motion control and torque delivery. Among these components, hypoid gear reducers occupy a critical position in applications demanding high torque density, compact form factors, and angular offset between input and output shafts.

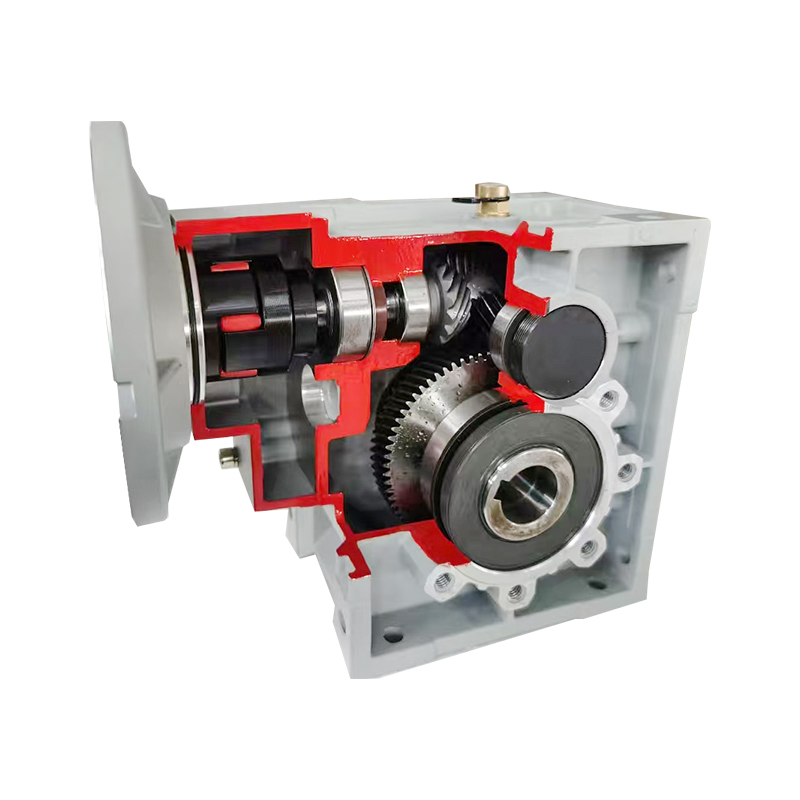

A BKM Hypoid Gear Reducer exemplifies a sophisticated gear reduction solution commonly deployed in sectors such as robotics, automated material handling, packaging equipment, aerospace ground support systems, and heavy duty machinery. These systems increasingly operate at higher duty cycles and tighter performance tolerances, imposing stringent demands on reliability and operational lifespan.

In this context, lubrication strategy emerges as a central determinant of system health. Effective lubrication directly influences wear mechanisms, thermal behavior, drivetrain efficiency, vibration characteristics, and maintenance intervals. Conversely, insufficient or inappropriate lubrication can precipitate accelerated surface fatigue, increased frictional losses, and premature component failure.

Industry Background and Application Significance

Role of Hypoid Reducers in Power Transmission Systems

Hypoid gear reducers are a class of spiral bevel gear sets which differ from conventional bevel gears by allowing non‑intersecting input and output shaft axes. This geometric arrangement affords:

- High torque transmission in compact volumes;

- Axial offset flexibility, facilitating space‑efficient drivetrain layouts;

- Smooth engagement due to overlapping, spiral tooth profiles.

These characteristics make hypoid reducers suitable for applications where angular repositioning, compactness, and torque demand converge.

Table 1 summarizes typical industrial applications for hypoid reducers and associated system requirements:

| Application Domain | Key Requirements | System Considerations |

|---|---|---|

| Robotics & Automation | High torque precision; repeatability; low backlash | Thermal stability; vibration damping |

| Material Handling | Heavy loads; continuous operation; shock loads | Durability; service interval optimization |

| Packaging Machinery | High throughput; synchronization | Noise control; efficiency |

| Aerospace Ground Support | High reliability; low maintenance | Environmental sealing; lubrication retention |

| Heavy Machinery | Over‑load tolerance; long duty cycles | Wear resistance; robust lubrication regimes |

In these contexts, the BKM Hypoid Gear Reducer is often selected for its capability to balance performance with integration flexibility. However, selection alone does not guarantee longevity; system‑level integration must account for lubrication dynamics, thermal behavior, and duty cycles.

System Engineering View of Gearbox Lifecycle

From a system engineering standpoint, the operational life of a hypoid gearbox is not solely a function of mechanical design. Instead, it is a composite outcome of:

- Design tolerances and surface geometry

- Lubrication and heat transfer mechanisms

- Load spectra encountered in application

- Control strategies (e.g., speed and torque profiles)

- Maintenance practices and diagnostics

The interplay between these factors dictates wear rates, failure modes, and mean time between failure (MTBF). Among these, lubrication is a modifiable parameter with outsized influence across the lifecycle, making it a focal point for both design and operational strategy.

Core Technical Challenges Related to Lubrication in Hypoid Reducers

Despite the critical function of lubrication, a series of technical challenges complicate its effective implementation in hypoid systems. These challenges are not limited to lubricant selection but extend into system architecture, dynamic response, and maintenance logistics.

1. Thermal Behavior and Heat Dissipation

Hypoid gear contact generates heat due to sliding and rolling interactions. In systems with continuous duty cycles, inadequate heat removal can:

- Accelerate lubricant degradation,

- Increase fluid viscosity beyond optimal ranges,

- Promote localized thermal softening of gear surfaces.

A comprehensive lubrication strategy must therefore address heat management in addition to friction reduction.

2. Load Spectrum Variability

Many industrial applications present highly variable load spectra. For example:

- Robotic joints switch between low and high torque repeatedly;

- Conveyors may experience intermittent shock loads;

- Packaging lines may operate at variable speeds with rapid acceleration/deceleration.

These dynamic loads impose fluctuating lubrication demands, making static lubricant prescriptions suboptimal in many cases.

3. Contamination and Seal Integrity

Lubricants exposed to external contaminants (e.g., dust, moisture, particulate ingress) can suffer accelerated wear and chemical breakdown. Seal integrity is thus a subsystem concern tightly coupled with lubrication system design.

4. Compatibility and Aging

Lubricant formulation must be compatible with gear materials, seals, and operating temperatures. Aging mechanisms, such as oxidation and additive depletion, influence lubricant performance over time.

5. Diagnostics and Predictive Wear Monitoring

Traditional maintenance models (e.g., time‑based oil changes) may not reflect actual wear conditions. Integrating lubrication strategies with diagnostics (vibration analysis, temperature sensors, oil analysis) introduces complexity but enhances system reliability.

Key Technical Pathways and System‑Level Solution Approaches

A disciplined lubrication strategy integrates selection, application method, monitoring, and maintenance planning as a cohesive system. The following sections outline these pathways with engineering focus.

Lubricant Selection: Understanding Viscosity, Additives, and Base Oil Chemistry

Lubrication begins with choosing the correct lubricant class. Key parameters include:

- Viscosity grade appropriate for speed and torque levels,

- Additive packages that support anti‑wear, anti‑oxidation, and EP (extreme pressure) performance,

- Base oil chemistry, which impacts thermal stability and aging behavior.

Although this article does not endorse specific products, engineers must align lubricant specifications with system conditions using data sheets and application engineering.

Considerations for lubricant selection:

| Criterion | Design Metric | Impact on Hypoid Reducer Behavior |

|---|---|---|

| Viscosity | Gear pitch line velocity; temperature range | Ensures film thickness and reduces metal‑to‑metal contact |

| EP Additives | Load cycles; shock loads | Protects gear surfaces under high contact stress |

| Oxidation Stability | Duty cycle; operating temperature | Extends lubricant life and delays varnish formation |

| Shear Stability | High‑speed operation | Maintains consistent viscosity under shear |

Engineers should evaluate lubricant performance under representative operating conditions, not just at standard test points. Simulation and bench testing often reveal behavior under dynamic loads, helping refine selection.

Lubricant Delivery Methods and System Configurations

Lubrication in hypoid reducers can be primarily categorized by delivery method:

- Splash lubrication

- Forced circulation systems

- Grease lubrication with periodic re‑lubrication

- Hybrid systems combining multiple approaches

Splash Lubrication

Splash lubrication uses gear rotation to entrain oil and distribute it within the gearbox. It is simple and cost effective but may not sustain film strength under high torque or temperature gradients.

Forced Circulation Systems

These systems employ pumps and filters to circulate lubricant through heat exchangers and distribution manifolds, supporting:

- Active thermal management

- Continuous distribution

- Filtration to remove particulates

Forced systems are typically paired with condition monitoring and are preferred in high‑duty industrial environments.

Grease Lubrication

Grease is used where fluid circulation is impractical. Grease packs provide lubrication but can struggle with heat removal and consistent film formation under variable loads.

Hybrid Strategies

In complex systems, engineers combine methods — for example, splash at low loads with periodic forced circulation during peak duty — to balance simplicity and performance.

The choice of delivery method should align with the system’s thermal profile, load spectrum, and maintenance regime. Table 3 outlines comparative attributes:

| Method | Heat Management | Film Consistency | Maintenance Demand | Application Suitability |

|---|---|---|---|---|

| Splash | Limited | Moderate | Low | Moderate duty, enclosed systems |

| Forced Circulation | High | High | Medium | High duty, critical reliability |

| Grease | Limited | Variable | High | Intermittent use, limited access |

System Integration: Sealing, Filtration, and Sensor Feedback

Beyond lubricant choice and delivery, system integration determines whether the lubrication strategy yields measurable lifetime extension.

- Sealing mechanisms prevent external ingress and lubricant egress.

- Filtration systems remove wear particles and contaminants, enhancing lubricant longevity.

- Sensor integration (temperature, vibration, pressure) enables feedback loops to detect anomalies before escalation.

An integrated lubrication system treats the gearbox as part of a larger cyber‑physical system, where sensor data informs maintenance decisions.

Typical Application Scenarios and System Architecture Analysis

To illustrate the application of lubrication strategy at a system level, consider the following example scenarios:

Scenario A: High‑Duty Robotic Arm in Automotive Assembly

System Requirements:

- Continuous operation in multi‑shift production

- Tight positional accuracy

- Frequent acceleration/deceleration cycles

Lubrication Strategy:

- Use of high‑viscosity synthetic fluid with EP additives

- Forced circulation with heat exchanger

- Integrated temperature and vibration sensors

- Scheduled oil analysis for wear particle detection

System Architecture:

In this configuration, the BKM Hypoid Gear Reducer integrates with a fluid circulation loop that includes:

- Pump Module — distributes lubricant at controlled flow rates

- Heat Exchanger — reduces operating temperature during peak loads

- Filtration Assembly — removes contaminants

- Sensor Suite — feeds real‑time data to controller

This architecture ensures consistent lubrication film, extends interval between onsite maintenance, and provides data for predictive diagnostics.

Scenario B: Packaging Line with Varying Throughput

System Requirements:

- Varying speeds based on product type

- Frequent startup/shutdown cycles

- Moderate continuous loads

Lubrication Strategy:

- Medium viscosity fluid with balanced additive package

- Splash lubrication supplemented by periodic forced circulation during high throughput periods

- Condition‑based monitoring triggers circulation system engagement

System Architecture Highlights:

The system adopts a dual stage approach:

- Normal operation uses splash lubrication for simplicity and low energy use

- When speed or temperature thresholds are reached, the forced circulation pumps engage automatically

This hybrid approach balances reliability and energy efficiency while avoiding unnecessary continuous circulation.

Impact of Lubrication Strategy on System Performance Metrics

Effective lubrication influences multiple performance dimensions:

1. Reliability and Lifetime Extension

Proper film formation reduces asperity contact, mitigating wear and delaying surface fatigue. A well‑managed lubrication regime can significantly increase MTBF and operational life.

2. Thermal Efficiency and Energy Consumption

Lubricants with appropriate thermal properties assist in heat transfer, reducing temperature gradients. This stabilizes material properties and reduces energy losses due to friction.

3. Noise, Vibration, and Harshness (NVH)

Consistent lubrication film dampens micro‑impacts between gear teeth, reducing acoustic noise and vibration. This is especially critical in precision automation.

4. Maintenance and Operational Cost

Although advanced lubrication systems have a higher initial cost, the reduction in unplanned downtime and longer service intervals typically yields lower life‑cycle cost.

Industry Development Trends and Future Technology Directions

The landscape of lubrication strategy for hypoid reducers is evolving. Several trends are emerging:

Condition‑Based and Predictive Lubrication Control

By leveraging sensor data and analytics, systems can adjust lubrication delivery dynamically, aligning with instantaneous load and temperature conditions. This reduces waste and enhances responsiveness.

Advanced Lubricant Formulations

Research into nano‑additives and smart fluids promises lubricants that change properties based on operational stress, potentially optimizing film formation and wear resistance.

Integration with Industry 4.0 and Digital Twins

Digital twin models allow simulation of lubrication effects within the larger mechanical system, enabling design optimization before physical deployment.

Sustainability and Environmental Considerations

Emerging standards are promoting lubricants that are more biodegradable and offer lower environmental impact without compromising performance.

Summary: System‑Level Value and Engineering Significance

In summary, the lifespan of a BKM Hypoid Gear Reducer is not dictated solely by mechanical design but is strongly influenced by the lubrication strategy implemented within the system. A comprehensive strategy encompasses:

- Selection of appropriate lubricant formulation

- Delivery mechanism tailored to load and duty cycle

- System integration with sealing, filtration, and sensing

- Data‑driven monitoring and maintenance planning

Such a strategy enhances reliability, reduces operational cost, improves performance metrics, and aligns with modern demands for smart, connected, and efficient industrial systems.

FAQ

Q1: What are the signs of inadequate lubrication in hypoid gear systems?

Signs include elevated operating temperatures, increased noise and vibration, visible lubricant degradation, and wear particle detection in oil analysis.

Q2: How often should lubricant be changed in a hypoid reducer?

Frequency depends on operating hours, load profile, temperature, and lubricant type. Condition‑based analysis is preferred over fixed schedules.

Q3: Can retrofitting sensors improve lubrication performance?

Yes. Adding temperature, vibration, and pressure sensors enables proactive adjustment of lubrication delivery and early detection of anomalies.

Q4: Is splash lubrication sufficient for all industrial applications?

No. Splash lubrication may suffice for moderate duty, but high duty cycles or precision motion systems benefit from forced circulation or hybrid strategies.

Q5: How do contaminants affect lubricant performance?

Contaminants such as dust or moisture accelerate wear, degrade additives, and increase friction, reducing system lifespan. Effective sealing and filtration mitigate these risks.

References

- Technical literature on gear lubrication from Industrial Gearing Journal, focusing on lubrication film formation and wear mechanisms.

- Engineering handbooks on power transmission and gearbox maintenance practices.

- System reliability texts addressing lubrication influence on MTBF and lifecycle cost.

05 Jun,2025

05 Jun,2025