The spiral bevel gearbox is a critical component in many industrial applications, providing reliable torque transmission and angular motion conversion. However, like any mechanical system, it is subject to vibration issues that can compromise performance, reduce efficiency, and lead to premature wear.

Understanding the spiral bevel gearbox

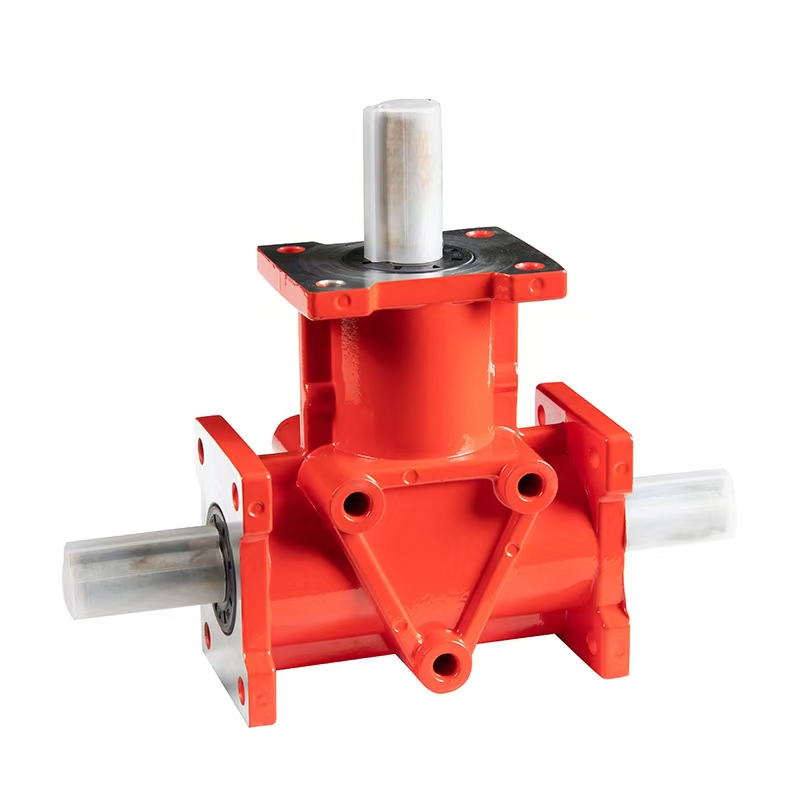

A spiral bevel gearbox is designed to transmit power between intersecting shafts, typically at a 90-degree angle. Its spiral teeth allow for smoother engagement, higher load capacity, and reduced noise compared to straight bevel gears. These gearboxes are widely used in industries such as material handling, mining, automotive production, cement processing, and marine equipment, where efficient torque conversion is required.

Despite their advantages, the complexity of the gear teeth and the interactions between shafts, bearings, and housing make vibration management an essential consideration in design, installation, and operation.

Common vibration issues in spiral bevel gearboxes

Vibration in spiral bevel gearboxes can arise from multiple sources, often interacting to create complex patterns. The most common issues include:

Gear misalignment

One of the primary causes of vibration is misalignment between the input and output shafts. Even small deviations can lead to uneven load distribution across the gear teeth. Misalignment typically manifests as periodic vibrations that increase with speed and load. In industrial settings, misalignment can occur during installation or due to thermal expansion over time. Preventive alignment checks and precision installation are critical to minimizing this type of vibration.

Gear tooth wear and pitting

Over time, gear teeth in a spiral bevel gearbox may experience wear, pitting, or surface fatigue. These conditions result in uneven meshing, generating high-frequency vibrations that can affect both efficiency and operational safety. Wear may be accelerated by inadequate lubrication, contamination, or excessive loading. Regular inspection of gear teeth and timely replacement of damaged components help mitigate this issue.

Bearing faults

Bearings support the shafts in a spiral bevel gearbox, and their condition significantly influences vibration levels. Worn, improperly lubricated, or damaged bearings can introduce radial or axial vibrations that propagate through the gearbox. Common symptoms include humming, rattling, or high-frequency vibrations detectable with vibration monitoring equipment. Bearing maintenance, including proper lubrication schedules and replacement intervals, is essential for vibration control.

Shaft imbalance

Shaft imbalance occurs when the rotational mass is unevenly distributed along the input or output shafts. In a spiral bevel gearbox, this imbalance can be caused by manufacturing defects, improper coupling installation, or material buildup. The resulting vibrations are often noticeable at higher speeds and can cause additional stress on gear teeth and bearings. Balancing shafts during manufacturing or service reduces this risk.

Gear backlash issues

Backlash refers to the slight clearance between mating teeth. While necessary for smooth operation, excessive or inconsistent backlash in a spiral bevel gearbox can lead to vibration. Increased backlash can result from wear, improper assembly, or incorrect gear mesh settings. Vibrations due to backlash often occur as oscillatory motion at low speeds. Adjusting backlash to manufacturer specifications helps maintain stability and minimize vibration.

Lubrication problems

Inadequate or contaminated lubrication is a frequent contributor to gearbox vibration. Spiral bevel gearboxes require proper lubrication to reduce friction, dissipate heat, and prevent wear. Insufficient lubrication increases friction between teeth and bearings, generating vibrations. Similarly, lubricant contamination with dust, metal particles, or moisture can accelerate wear and create vibration. Regular monitoring of lubricant quality and replacement intervals is vital.

Resonance and structural vibration

In some cases, the gearbox housing or mounting structure can amplify natural frequencies, resulting in resonance vibrations. These vibrations can appear as periodic or fluctuating amplitudes during operation. Structural issues such as loose bolts, flexible mounts, or insufficient rigidity in supporting frames may exacerbate resonance. Ensuring secure mounting, robust housing design, and damping measures are effective ways to prevent structural vibration.

Effects of vibration on spiral bevel gearboxes

Vibrations in a spiral bevel gearbox are not merely an operational inconvenience; they can have serious consequences, including:

- Accelerated wear of gear teeth and bearings.

- Reduced efficiency, leading to higher energy consumption.

- Excessive noise, which can affect workplace safety.

- Component fatigue, potentially causing catastrophic failure.

- Increased maintenance costs due to more frequent inspections and replacements.

Understanding these impacts helps buyers and engineers prioritize vibration control in both selection and operation of spiral bevel gearboxes.

Diagnosing vibration issues

Effective diagnosis of vibration in a spiral bevel gearbox involves a combination of visual inspection, acoustic analysis, and vibration measurement. Common techniques include:

- Vibration spectrum analysis: Identifies frequencies associated with specific faults such as misalignment, imbalance, or bearing wear.

- Thermal imaging: Detects hotspots caused by friction or inadequate lubrication.

- Oil analysis: Reveals contamination and wear particles that may indicate gear or bearing deterioration.

- Visual inspection: Detects pitting, cracks, or misalignment that may be contributing to vibration.

A structured maintenance schedule that incorporates these diagnostic methods allows for early detection and mitigation of vibration issues.

Strategies to reduce vibration

Minimizing vibration in a spiral bevel gearbox requires a combination of design, operational, and maintenance strategies:

Precision installation

Proper alignment, secure mounting, and accurate coupling installation are essential. Using laser alignment tools or precision measuring equipment ensures that shafts and gear teeth are correctly positioned.

Lubrication management

Selecting the appropriate lubricant type and viscosity, along with maintaining regular replacement intervals, reduces friction-induced vibration. Synthetic lubricants may offer enhanced stability under varying temperatures and load conditions.

Regular inspection and maintenance

Scheduled inspections of gear teeth, bearings, and shafts help identify early signs of wear or misalignment. Implementing a predictive maintenance approach using vibration sensors can further minimize unplanned downtime.

Structural improvements

Reinforcing gearbox housings, securing mounting frames, and employing vibration-damping materials help prevent resonance and structural vibrations. Proper torque of mounting bolts and vibration isolation pads can be particularly effective in heavy machinery applications.

Load management

Operating the spiral bevel gearbox within its rated torque and speed specifications reduces excessive stress on components. Avoiding sudden load spikes and transient overload conditions prevents vibration-related failures.

Industry applications sensitive to vibration

Certain industries are particularly sensitive to vibration issues in spiral bevel gearboxes. Examples include:

| Industry | Vibration Concerns | Importance of Control |

|---|---|---|

| Material handling | Heavy and uneven loads | High |

| Mining | Abrasive materials and shock loads | High |

| Automotive production | Precision assembly lines | Medium |

| Cement processing | Continuous heavy-duty operation | High |

| Marine equipment | Variable torque and harsh conditions | High |

In these applications, vibration control is not only a matter of performance but also of safety and reliability.

Conclusion

Vibration in a spiral bevel gearbox is a multifaceted issue that can arise from gear misalignment, tooth wear, bearing faults, shaft imbalance, backlash, lubrication problems, and structural resonance. The consequences of unmanaged vibration include accelerated wear, reduced efficiency, noise, and potential system failure. By understanding the sources of vibration and implementing preventive measures such as precision installation, lubrication management, regular inspection, structural reinforcement, and load control, engineers and operators can maintain reliable performance and extend the operational life of spiral bevel gearboxes.

Ultimately, recognizing the critical role of vibration monitoring and proactive maintenance ensures that spiral bevel gearboxes continue to deliver the torque transmission efficiency and durability required in demanding industrial environments.

05 Jun,2025

05 Jun,2025